Around the ever-evolving landscape of manufacturing and layout, the capacity to control and transform resources into functional and aesthetically pleasing components is vital.

Amongst the diverse variety of processes offered, Plastic Fabrication stands as a cornerstone, offering a amazing level of adaptability and modification for a large spectrum of applications. From elaborate clinical gadgets to durable industrial parts, and from streamlined customer electronics housings to appealing signage, the impact of knowledgeable Plastic Manufacture is undeniable, forming the globe around us in plenty of methods.

At its heart, Plastic Manufacture encompasses a variety of methods used to cut, form, mold, sign up with, and coating plastic materials right into preferred types. Unlike mass production techniques like injection molding, Plastic Construction commonly concentrates on reduced volume production, prototypes, custom-made layouts, and larger or much more intricate components that might not be financially feasible with other procedures. This integral versatility makes Plastic Construction an invaluable tool for engineers, developers, and companies throughout numerous industries.

The charm of Plastic Construction depends on the diverse toolbox of techniques it includes. Skilled makers use techniques such as CNC machining, where computer-controlled devices precisely reduced and shape plastic sheets, rods, and obstructs according to digital styles. This technique supplies remarkable accuracy and repeatability, making it excellent for elaborate get rid of limited tolerances. Laser reducing offers another precise technique for cutting complicated forms and complex information from plastic sheets, often leaving clean and sleek sides.

Past subtractive approaches, Plastic Construction additionally consists of formative methods. Plastic welding, making use of numerous methods like ultrasonic, hot plate, or solvent welding, permits the irreversible joining of plastic elements, creating solid and smooth bonds. Thermoforming, as reviewed previously with vacuum creating, involves home heating and shaping plastic sheets over mold and mildews, providing a cost-efficient service for producing rooms, trays, and other contoured parts. Flexing and creating techniques, often using warm, allow for the production of complex three-dimensional shapes from plastic sheets and rods.

The selection of the suitable Plastic Manufacture technique depends upon a multitude of factors, including the sort of plastic product, the complexity of the design, the needed tolerances, the production quantity, and financial restraints. Experienced Plastic Manufacture service providers have the competence to evaluate these aspects and suggest the most reliable and affordable technique for each task.

The applications of Plastic Fabrication are unbelievably diverse and continue to expand as material science and fabrication innovations advance. In the clinical market, Plastic Construction plays a critical function in creating custom implants, medical overviews, diagnostic gadgets, and tools housings that satisfy stringent regulative demands. The aerospace and protection industries depend on Plastic Construction for light-weight and resilient parts utilized in aircraft insides, drone components, and protective equipment.

Customer electronic devices benefit exceptionally from Plastic Fabrication in the creation of sleek and practical housings, bezels, and inner elements. The retail and signage industries use Plastic Manufacture to produce eye-catching display screens, point-of-sale products, and durable signs that withstands various ecological problems. Also the building and building markets take advantage of Plastic Manufacture for producing customized cladding, skylights, and attractive components.

Picking a reputable and skilled Plastic Fabrication provider is Plastic Fabrication extremely important for guaranteeing the success of any type of task. A trusted maker will have a deep understanding of numerous plastic materials and their buildings, the capabilities and constraints of various fabrication techniques, and the significance of quality control throughout the whole procedure. They can use valuable layout appointment, assisting to maximize parts for manufacturability and cost-efficiency.

Furthermore, lots of Plastic Fabrication firms supply a series of value-added services, including completing (such as sprucing up, paint, and coating), assembly, and even product packaging. This thorough strategy can streamline the manufacturing process and give a solitary point of get in touch with for all your Plastic Manufacture needs.

Finally, Plastic Fabrication stands as a vital and functional technique within the world of manufacturing. Its capability to change a wide variety of plastic materials right into custom-made components with a diverse variety of methods makes it an crucial device for technology throughout various sectors. As technology continues to breakthrough and the need for specialized plastic parts expands, the competence and capacities of experienced Plastic Fabrication provider will certainly stay essential in shaping the future of item design and production. Whether you call for a single prototype or a tiny set of customized parts, checking out the possibilities offered by seasoned Plastic Manufacture can open a world of crafted polymer options for your details demands.

Mara Wilson Then & Now!

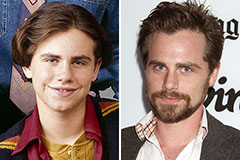

Mara Wilson Then & Now! Rider Strong Then & Now!

Rider Strong Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now!